Faster, Smarter, Stronger: AWL’s new Sprinkler Pipe Machine sets the standard

Published on: Aug 7, 2025

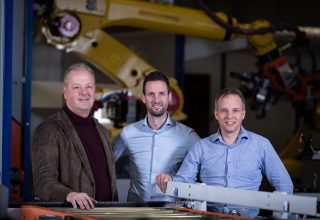

Back in 2005, AWL launched its first fully automated machine for producing prefab sprinkler pipes. Over the years, it went through several smaller upgrades – but now, there’s a completely new generation: faster, smarter, and safer than ever. “We’ve built on twenty years of experience,” says Technical Sales Engineer Cees-Jan Braam. Together with Account Managers Rens Driessen and Kent Carpenter, he explains the innovations behind Sprinkler Machine 2.0.

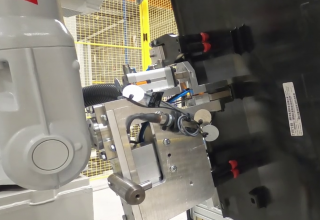

Every weld spot-on, even size-on-size

One of the biggest breakthroughs is pipe rotation. “The pipe now rotates during welding, which creates much more consistent welds – even for complex joints,” Rens explains. “Especially with size-on-size welds – where the outlet’s outer diameter matches that of the pipe – quality issues can occur. By rotating the pipe, we always weld at the ideal angle and prevent the weld pool from sagging due to gravity. Plus, pipes are never perfectly straight – we embraced that fact and engineered a clever solution that can handle those natural curves without issue.”

Up to 80 outlets per hour: speed through smart integration

With the new machine, standard pipes can now be processed at up to 80 outlets per hour. “For pipes with only 10 outlets, output could theoretically be even higher because there’s less handling per pipe,” says Cees-Jan. “But here’s what really matters: we maintain that 80 even when welding just two outlets per pipe. Competitors see their speed drop sharply in that case.”

This high throughput comes from seamless integration of every process step. “As a system integrator, we bring decades of experience from industries like automotive. Optimizing individual steps into a fast, stable, fully integrated solution – that’s what we’ve pushed to the max for the sprinkler industry.”

More output, fewer welders

Beyond quality and speed, automation also tackles the industry’s labor shortage. “It’s nearly impossible for a welder to deliver perfectly consistent results during an eight-hour shift,” says Rens. “Our machine replaces the output of three to four semi-automated units or six manual welders. The robot runs non-stop with flawless consistency. With an estimated 300,000 welder shortage by 2028, that’s a real game changer.”

Safe, Stable, and Ergonomic

Safety was a top priority in designing the new machine. “Some customers handle pipes weighing 770 lbs (350 kg) and over 20 feet (6 meters) long,” Cees-Jan explains. “That needs to stay safe and manageable. So, the pipes are locked between two grooving machines for stability during processing. The operator no longer has to physically restrain the pipe – which is especially tough with long sections – making the job safer and more ergonomic. Controlled pipe loading and unloading further ensures operator safety. Plus, because the operator is never above the weld arc or exposed to fumes, the overall work environment is much healthier.”

Fast diagnosis, minimal downtime

Maintenance and support are equally smart: in the rare event of a malfunction, AWL can troubleshoot remotely. Any AWL programmer can log into the system software, identify the root cause, and fix issues without unnecessary downtime. The machine also automatically logs all error messages and tracks every single pipe for full traceability.

Peace of mind maintenance after the sale, included

AWL offers different tailored service solutions to keep your production running smoothly. From Annual Maintenance Support Plans (MSPs) and Master Service Agreements to hands-on training programs for your operators, we know what it takes to support you. “In North America, I include the MSP offering on all of my General Industry machine builds,” says Kent. He continues: “For many of my customers, this may be their first robot or automation experience. We developed the MSP service product to assist our customers in making this technology leap with four visits after the sale in an effort to ensure a smooth next-level automation journey”.

Standard or Advanced? The choice is yours

The new sprinkler machine comes in two variants. The standard version automates welding of outlets: feeding, measuring, welding, and unloading pipes. The advanced version adds extra capabilities: cutting, deburring pipe ends, grooving, optional labeling for identification, and even a second robot with a milling tool to remove zinc coating on galvanized pipes prior to welding.

For fully integrated production, customers can also connect their BIM system directly to the machine. “Choosing standard or advanced depends on each customer’s production setup and job mix,” says Cees-Jan. “Either way, you get maximum efficiency and sustainability. The advanced model optimizes material usage to produce more pipes per stock length, leaving virtually zero waste. That’s a big advantage.”

From intimidation to confidence: The Smart Sprinkler Tool

A common concern when introducing robots is programming the distinctive pringle-shaped weld seam. “Customers often think, ‘I’ll never be able to do that,’” says Cees-Jan. “But with our Smart Sprinkler Tool, they don’t have to.”

The tool uses pipe and outlet geometry plus a few operator inputs – like weld speed and width – to automatically generate the robot’s weld path. “It saves enormous programming time and is very user-friendly,” he says. All pipe-outlet combinations are quickly and accurately defined, enabling customers to easily add new pipe and outlet types over the machine’s lifetime – no programming expertise required.

Proven performance in the field

The new machine has already been successfully delivered worldwide. Rens recalls one customer who made his decision without even looking at the machine. “He just watched the operators’ faces as they worked with it. Seeing their confidence was all he needed.”

Another customer bought the previous model in 2022 and saw such a dramatic production speedup that employees could wrap up their shifts early. “They recently ordered the new machine to push output even further,” says Rens.

Discover what it can do for you

Curious how the new sprinkler machine can transform your production process? Contact one of our account managers. They’ll help configure the right solution – standard or advanced, with the options that fit your needs – and can arrange a reference visit if you’d like to see it in action.

The future of your production starts now

Our new sprinkler machine delivers next-level performance – tailored to your needs. Standard or advanced, with smart options to match. Contact our account managers to discover what it can do for you. Want proof? We’ll set up a reference visit.

Don’t wait. Get ahead – and stay ahead.

You will also like these blogs:.

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026

Small footprint, big impact: automating sideskirt clipnut assembly