Arc welding

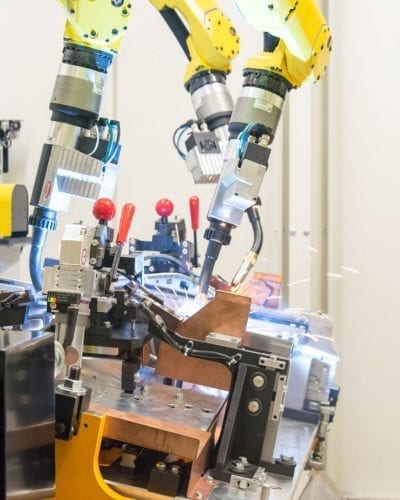

Quality through electronically controlled equipment and advanced robotics

In both the automotive and metal processing industries, arc welding is a renowned joining method. Many metals can be welded with this process, such as steel, stainless steel and aluminum. The majority of our customers use this technique in combination with robot automation. In arc welding, you have MIG/MAG welding, MIG soldering and TIG welding.

MIG/MAG welding is the most widely used arc welding process when it comes to robotic arc welding. The process can be perfectly automated and deployed quickly and with a low threshold. Through our years of experience, we can optimally process arc welding in a machine concept.

Due to the widespread use of robotic arc welding, robot suppliers also invest a great deal of energy in this technology and develop advanced capabilities focused on arc welding. This ranges from improving path accuracy to specific software functionality.

A special application in this respect is the use of a welding cobot in the welding process, because, after a short period of training, a cobot enables you to achieve high welding precision. AWL has introduced Qube – a cobot welding cell – for this purpose.

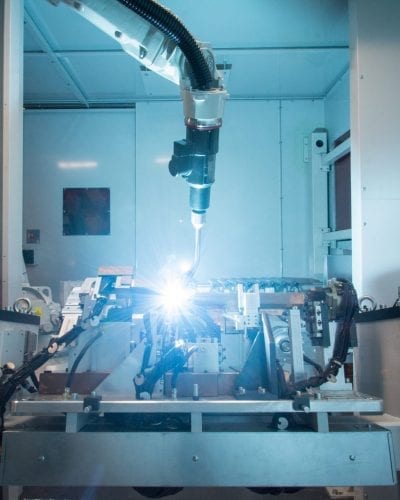

The arc welding equipment has evolved over the decades from analog to the fully digital control of both the welding process and the wire feed. In recent years, the wire feed has also been made reversible, allowing excellent control of the arc stability and character. Thanks to these developments, with the current state of the art, the penetration, heat input and spattering behavior can be controlled optimally, benefitting both quality and speed.

Development

Our Research & Development department investigates and optimizes the welding times of the various robot equipment combinations. The goal is to offer optimum output with maximum reliability. Test programs are carried out for new equipment possibilities in terms of features and material use. Another key topic is the automatic inspection of welding seams. Laser triangulation offers interesting possibilities for automatically inspecting welding seams. This avoids the costs of having an operator perform the inspection and at the same time also improves the inspection’s reliability. In the future, digitalization will offer opportunities to adjust process parameters automatically to benefit improved quality and efficiency.

Would you like to know if arc welding best suits your products?

Let AWL advise you.