Digitalization

Data is the key to optimization

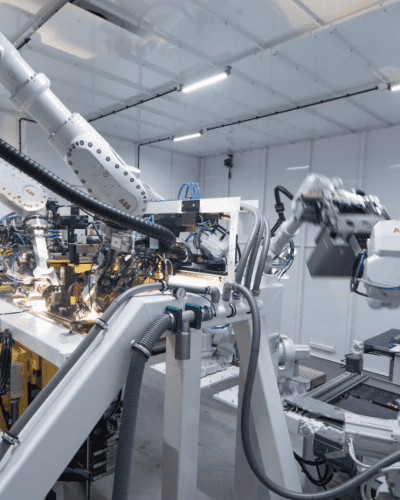

The market is changing and transforming. AWL is also part of this and is developing from a traditional machine builder to a machine software and IT specialist. Digitalization creates insights into the productivity of machines and plants. And with increasing factory automation, the need for tools to control and manage the process is becoming increasingly important. Through digitalization, we can provide you with data and help you significantly improve your productivity. Digitalization enables us to provide you with data that helps to control your production process better.

Example

In a customer’s factory, we were asked to analyze the production output in detail during the production time. A significant drop in productivity was seen in the last 20-30 minutes of the shifts. Once this was recognized, the issue could be solved. In this way, the customer can make a data-driven improvement process. Without the data analysis, the issue would not have become known to the factory managers.

AWL is developing from a traditional machine builder into a specialist in the field of machine software and IT.

Service

We recognize that collecting data can offer great insight into a production process. AWL would happily discuss how and what machine and process data should be collected. We can store and visualize this data for you, providing an excellent opportunity to carry out service and problem analysis. Would you also like more insights into machine maintenance, process optimization, logistics, and finance? At AWL, we have people in-house who specialize in developing applications that can help you do just that.

The future

How do we see the future? We believe that Digitalization will enable a flexible production system with a high level of productivity. In the future, machines will be given self-learning and monitoring functionalities, helping our customers increase their productivity. This will involve controlling production results and preventive maintenance through production dashboards, training assistance for operators and maintenance personnel and algorithms that automatically adjust process quality.

Interested in our vision on digitalization?

Please feel free to contact us.