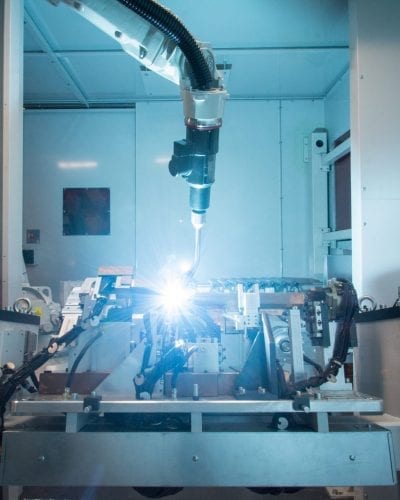

Steel welding

Welding different types of metal presents challenges. New types of steel are still coming on the market and the welding processes are being developed further. AWL continues to conduct research into this and can therefore apply a wide variety of joining techniques.

Welding steel

AWL has extensive experience in welding all types of steel for a very diverse range of applications in the automotive and metalworking industries. For many years, AWL has also successfully applied the various welding processes, such as spot welding, arc welding, laser welding as well as adhesive bonding.

This does not mean that steel holds no more secrets for AWL and that all results are known in advance. New types of steel are still coming on the market and the welding processes are being developed further. To ensure the success of a process in advance, AWL employs many experts, such as IWEs (International Welding Engineers) and IWTs (International Welding Technologists). Also, equipment for performing tests, such as robots with state-of-the-art arc and spot-welding equipment, and even an automated laser welding cell are present in the Experience Center. Before the start of a project, this enables AWL to assess its feasibility and make an initial adjustment of the welding parameters in advance.

The steels that are welded with the AWL machines are very diverse: ranging from traditional deep-drawing steel to all kinds of stainless steel. AWL is open to working with you to test the steel type for your project and explore the feasibility of an automated welding system!

Do you have a question for one of our experts? Or would you like to request a quotation?