Laser cleaning

Laser cleaning is a surface treatment that uses pulsed laser light.

Laser cleaning is a friendly cleaning process that does not require any solvents. The products are cleaned contactless without damaging them.

Possible uses of laser cleaning machines

Laser cleaning been in use in an industrial context, especially in automated configurations, since the 2000s. AWL has a great deal of in-house knowledge about machine construction, automation and laser welding.

This combination enables AWL to perfectly incorporate laser cleaning technology into its machines. We have cast our operational and practical knowledge into the development of our own machines, built for our customers.

Technology

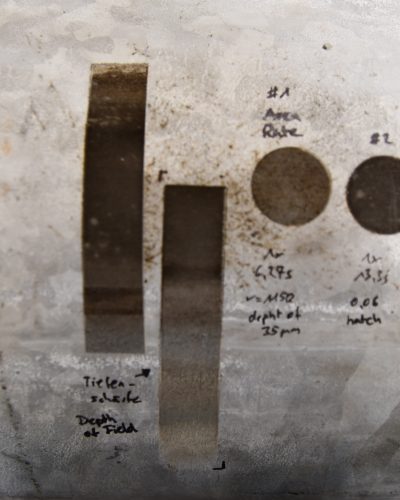

Laser cleaning uses the pulsed laser ablation principle: the laser pulse is transmitted to the surface and penetrates the contaminant, after which it reflects off the substrate. A combination of different processes creates a gas layer between the substrate and the contaminant that ensures the contaminant comes loose. The released substances are trapped, as a result of which there is no dirt blowing around.

Benefits

• No damage to the substrate

• No secondary waste, such as solvents or contaminated blasting grit

• No air displacement

• Very pure result

• Minimum logistics preparations

• Applicable in difficult-to-reach places

• Safe removal of toxic substances

• Human and environment-friendly technology

These benefits will reduce the total cost of ownership of your machines and products, and increase the efficiency of the production.

We can help you with automated laser cleaning.

Contact us to become further acquainted!