From Manual Check to Smart Control: Discover AWL’s AI Weld Inspection Solution

Published on: Sep 9, 2025

In the automotive and metal-processing industries, weld inspection is often still done manually, which can be time-consuming and error-prone. But with a structural shortage of operators, this is becoming increasingly challenging. At the same time, organizations want to digitally record inspection results in systems such as ERP or MES. The demand for consistent inspection quality and complete traceability is also growing. Can inspection be done smarter? “Absolutely,” says Wilbert van de Ridder, Innovation Leader at AWL’s R&D department. In this blog, you’ll read how AWL, together with partners, developed the smart and flexible AI weld inspection solution. Curious how that works? Read on!

Between manual and high-end: the missing link

“For automated weld inspection, 3D technology solutions have been around for some time,” Wilbert explains. “These create a three-dimensional image of the weld and run calculations on it. But that approach is expensive, the cycle time is relatively long, and integration into existing machine concepts is limited. For many organizations, it’s overkill compared to manual inspection. That’s why more and more customers asked us: isn’t there a solution between manual checks and 3D inspection? That question was the starting point for developing the AI weld inspection solution.”

From idea to development

“At first, we explored whether any of our suppliers already had a ready-made solution, but the answer was ‘no,’” Wilbert continues. “So our R&D team started a development journey. The first step: mapping out exactly what an operator does during inspection and what they pay attention to. Based on this, we defined the scope and set the minimum requirements for our solution. Next, we built a test setup, including software, to gain a deeper understanding of the inspection process. This ensured we were well-prepared for discussions with potential suppliers.”

Co-development with four strong partners

The goal was clear: if a complete solution existed in the market, AWL would gladly embrace it. But market exploration quickly showed that no existing solution fully matched our needs. “Some players were working on such systems,” Wilbert explains. “We evaluated 32 potential suppliers, of which twelve met our initial criteria. We assessed references, domain expertise, and collaboration potential. AWL always strives for co-development—building solutions together with partners that truly work in practice. In the end, we selected four partners: Vista Solutions, IUNA, Vitronic, and Mapvision. Two of these are already integrated into our internal evaluation environment. One solution has been sold and is currently in design and build.”

Flexible and always the right fit

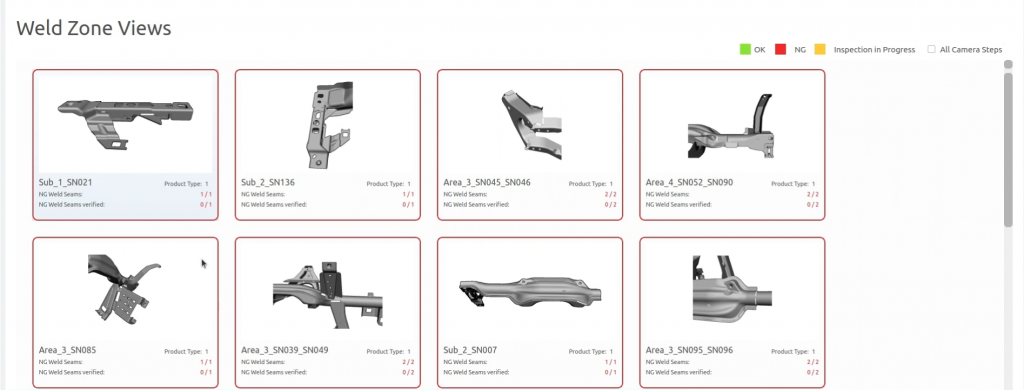

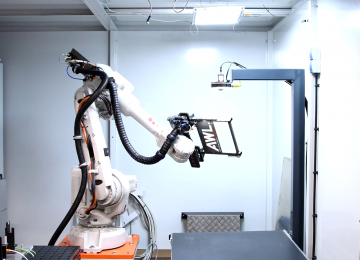

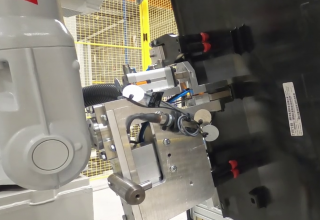

The AI weld inspection solution uses a 2D camera to capture an image of the weld, which is then analyzed by AI software. Wilbert: “Our partners take different approaches. Some use models pre-trained on large datasets, others focus on efficient training of new models per project. Pre-trained systems can offer faster setup times, but if a customer case doesn’t match a pre-programmed model, that advantage disappears - and then other solutions may be a better fit. This way, we can always offer the best match.

If a customer prefers their own supplier, we’re open to that too. AWL is, after all, a system integrator - flexible in our approach and focused on delivering the optimal solution for the customer. That’s why the AI weld inspection solution can be applied in multiple ways: integrated in-line in a machine, or set up outside the machine.”

More than just a visual check

The AI weld inspection solution is not a replacement for 100% inspection, but it is an alternative to visual quality control. The system checks whether the weld is present, whether it’s in the correct position, and measures dimensions with millimetre-level accuracy. It also detects visual surface defects such as burn-throughs, interruptions, and pores.

On top of that, the unit offers additional functionalities: detecting weld spatter, reading barcodes, performing dimensional measurements, and verifying the presence of all assembly components. Wilbert: “The strength lies in the combination of simplicity, flexibility, and intelligence.”

The next step in smart weld inspection

The AI weld inspection solution is particularly suitable for sectors where arc welding is a key part of production. Think of the automotive industry, but also the broader metal-processing industry. The first project has already been sold, and several more are in the pipeline. “Interest is growing, and together with our partners, we want to further develop the solution for new applications. For example, we’re also exploring inspection for other welding processes and joining methods such as gluing,” says Wilbert.

See the AI weld inspection solution in action

From September 15–18, 2025, the AI weld inspection solution will be showcased at the Schweissen & Schneiden trade fair in Essen, Germany. Curious what the solution could mean for your production process? Visit AWL’s Experience Center in Harderwijk. Wilbert: “Anyone interested in automating weld inspection is warmly invited to see our solution in action. We’ll gladly discuss the right scope and, of course, the machine concept.”

Want to experience how your inspection process can become smarter and faster?

Plan an online introduction or book a demo today.

You will also like these blogs:.

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026

Small footprint, big impact: automating sideskirt clipnut assembly