In conversation about the future of the food industry: insights from an inspiring roundtable session

Published on: Feb 12, 2026

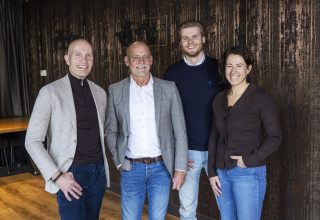

During an inspiring roundtable session organized by ING and Vakblad Voedingsindustrie, leaders from across the food industry explored the challenges and opportunities of innovation, automation, and collaboration. Participants included Emiel Boogaard (Goedhart Bakery Kitchen Group), Jantine Heemskerk (Heemskerk fresh & easy), Philip Lutke Veldhuis (VIT), and Gerard Ramaker (AWL).

The central question: How can food companies remain agile in a market defined by rising costs, labor shortages, and ever-increasing customer expectations?

Creativity, courage, and persistence

Innovation rarely follows a smooth or predictable path. Developing new technologies requires significant investment, experimentation, and resilience. As Jantine Heemskerk puts it, “It’s often plug and pray instead of plug and play.” True progress depends on creativity, intrinsic motivation, and the courage to take risks. Companies must be willing to experiment, accept setbacks, and continuously learn.

From AWL’s perspective, Gerard Ramaker highlights the rapid evolution of robotics, vision systems, gripper technology, and artificial intelligence. Today’s robots are no longer limited to repetitive tasks: they can see, sense, analyze, and collaborate. These capabilities are transforming production processes and opening entirely new possibilities for the food industry.

Putting people at the center of innovation

While automation is accelerating, people remain central to successful innovation. Technology should support employees, reduce physical strain, improve safety, and create more engaging work environments. By actively involving employees in innovation projects, companies increase engagement, ownership, and acceptance of change. The result: smoother implementation, stronger teams, and higher overall performance.

Collaboration as a catalyst for progress

One key takeaway from the discussion: innovation thrives through collaboration. No company can do it alone. Partnerships with technology providers, startups, and knowledge institutions are essential to accelerate development and reduce risk. At AWL, close collaboration with customers is fundamental. Co-creation leads to tailor-made automation solutions that seamlessly integrate into production processes, delivering real, measurable impact.

Innovation with a sustainable mindset

Automation and sustainability increasingly go hand in hand. Smart production systems help reduce waste, optimize energy consumption, improve product quality, and use resources more efficiently. At the same time, sustainable innovation requires a long-term vision, stable partnerships, and strategic investments. When done right, sustainability, innovation, and profitability reinforce each other.

Conclusion

The roundtable session makes one thing clear: innovation in the food industry is no longer optional; it is essential.

True progress happens where technology, people, and collaboration come together. By sharing knowledge, co-creating solutions, and continuously improving, companies can build resilient, future-ready operations that make a lasting difference.

Source: Magazine Voedingsindustrie by Judith Witte | photos ©Herbert Wiggerman

You will also like these blogs:.

Live AWL demos at LogiMAT & MODEX – Turn intralogistics challenges into scalable robotic automation

AWL Mexico through the lens of its Managing Director Lucas Diaz

In conversation about the future of the food industry: insights from an inspiring roundtable session