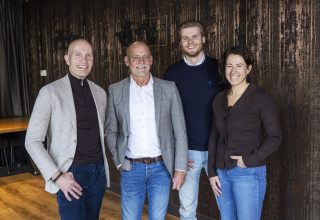

Meet The People | Rutger Boxum: From project coordinator to driver of change

Published on: Sep 25, 2025

From project coordinator to driver of change: Rutger’s journey at AWL is all about curiosity, practical knowledge, and a strong passion for improvement. As a continuous improvement manager, he helps colleagues work smarter and more efficiently every day - while ensuring that improvements take root and become a lasting part of the organization.

Rutger (38) lives in Zwolle with his wife and children. His career began in 2010, right after completing his studies in Human Resource Management and Industrial Management. He started out as a work planner at a shipbuilder in Kampen.

“We built enormous seagoing vessels there. I love manufacturing, creating something tangible. It makes you proud - just like my passion for renovating. Being hands-on, making great things, but also thinking about how to approach things smartly, that really suits me,” Rutger says.

After three and a half years, AWL crossed his path. “What immediately appealed to me was that AWL operates in a very dynamic environment. It’s about projects, of course, but especially about the people who bring those projects to life. I quickly noticed that there’s room for initiative and personal influence. At the same time, AWL is strongly technology-driven. Tackling challenges and finding solutions - that DNA runs through the company. It was a perfect fit with my background and interests.”

In 2014, Rutger joined as project coordinator, a role where he could fully apply both his organizational skills and technical knowledge. “The best part of that role was the building process itself. You start with an empty concrete floor in our own facility, and months later, thanks to intensive teamwork, a fully functioning machine is delivered to a satisfied customer. That really gives you a kick. You can literally see what you’ve achieved together. During that period, I learned a lot about AWL’s technology, but also about myself.”

After five years, he transitioned to team leader nominal assembly (now team leader production). In that role, he worked with mechanical and electrical assemblers on the physical build of machines. “It gave me the chance to tackle the challenges I had encountered as project coordinator. The areas that didn’t run smoothly, I could now improve. Optimizing processes, spotting opportunities, and really doing something with them - that increasingly became my passion.”

When AWL’s focus on continuous improvement grew further, moving into the role of continuous improvement manager in 2021 was a natural next step in his career.

Continuous improvement at AWL

As continuous improvement manager, Rutger ensures that improvements at AWL are not only identified but also truly embedded in the organization. Together with his team, he does this based on the principles of Operational Excellence. “While colleagues focus daily on the primary processes, I think about how we can collaborate more effectively. Where do we need to focus more attention? And how do we make sure that a change delivers lasting results? The challenge is to create a structure that can be applied everywhere: in the Netherlands and across our international sites, while remaining flexible enough. Ultimately, it comes down to people’s intrinsic motivation; you can’t force change. Explaining, demonstrating, trying again - that’s how you make change stick and ensure it lasts.”

A typical workday for Rutger is highly varied. “Sometimes I work on new tools or translate strategy into a practical plan. At other times, I support a Business Unit in achieving its goals or dive deep into a specific process. The core is always the same: I help define how we approach something - which tool, which steps, who’s involved, and how it will be safeguarded. Some departments are already highly experienced, while others are less so. That’s why I lead, prepare, and support in both small and large matters. Sometimes I even go into detail, such as a business plan or a technical issue. That’s important to me; it keeps me sharp and close to the practice. Ultimately, my role is to bring overview and consistency, so departments can successfully drive improvements themselves.”

Pride and challenges

Rutger is proud of the structure his team has built and how it has been embraced by the departments. “Continuous improvement is now clearly on the AWL map. We’ve laid a foundation that works. It’s great to see colleagues adopting this approach. It’s truly been a cultural shift.”

But improvement is more than just drafting a plan. “The challenge is in the balance: providing structure while staying flexible. AWL isn’t a standard company; you have to adapt, be patient, and understand the dynamics. At the same time, we observe that many of our challenges are similar to those faced by other companies. That means there are plenty of improvement tools that fit us well.”

A key difference compared to a few years ago is the way Business Units now set their goals. Historical insights are actively used to shape plans for the future. “From the Operational Excellence perspective, you work in as standardized a way as possible. That makes results predictable and reliable, saving time. Time we can then spend on more complex challenges.”

Not everyone was convinced right away. Engineers initially saw standardization as a threat to their creativity. Rutger smiles: “It’s not about standardizing technical solutions, but the processes around them. Once that insight clicks, a whole new world opens up.”

Driven by curiosity

Rutger sees opportunities everywhere to make things work smarter. “If something isn’t running smoothly, it keeps bothering me until I find a solution. That applies at home, but even more so at work. That’s where the real opportunities lie. I like to gather input from colleagues and use data to gain new insights.”

Outside of work, he also enjoys combining thinking and doing. Renovating is one of his big passions. “It brings together everything I love: preparation, being hands-on, keeping oversight, and physically building.”

If he had to describe himself in three words, Rutger would say: structured, analytical, and practical. And it’s exactly that mix that makes him the driving force behind continuous improvement at AWL.

Rutger’s tip

“When you run into a problem, go to the place where it happens and talk to people. From behind a desk, you’ll rarely find the real solution. And above all: be proud of what you achieve together with your team.”

You will also like these blogs:.

Live AWL demos at LogiMAT & MODEX – Turn intralogistics challenges into scalable robotic automation

AWL Mexico through the lens of its Managing Director Lucas Diaz

In conversation about the future of the food industry: insights from an inspiring roundtable session