Responding to customer needs with a modular laser cell

Published on: Apr 13, 2018

Fully automated machines, a greater need for quality control and machine data which customers need; all are on the increase. This also means that machines are becoming more complex. It is a challenge to get all innovations in balance, to restrict the complexity, to reduce costs and at the same time to shorten lead times. AWL responds to this with the newest innovations and techniques, implemented together in a modular laser cell.

AWL has more than 15 years of experience with laser welding and in the past years, AWL has gained a significant amount of knowledge with modular machine concepts in arc and resistance welding. The knowledge gained has been used to help design a modular laser cell.

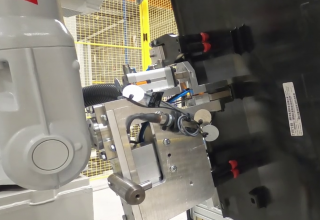

A modular cell does not consist of one single constructed cell, but of separate modules. Depending on the customer's choice, AWL selects fixed modules. For instance, AWL is building a cell for a customer consisting of three modules: a module with a turntable, an operator module and a module with the robot. Working with fixed modules enables AWL to construct the machine based on the production needs and growth of its customers. In this way, customers can connect with global business development and the flexible implementation of production capacity.

The objective of delivering a modular laser cell is to reduce the lead time by 50%. A modular cell also makes it easier to reuse components. Finally, this modularization enables AWL to deliver the same quality to its customers worldwide, adjusted if necessary to local needs. For instance, we have built and delivered modular cells in both China and the United States.

You will also like these blogs:.

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026

Small footprint, big impact: automating sideskirt clipnut assembly