Small footprint, big impact: automating sideskirt clipnut assembly

Published on: Nov 27, 2025

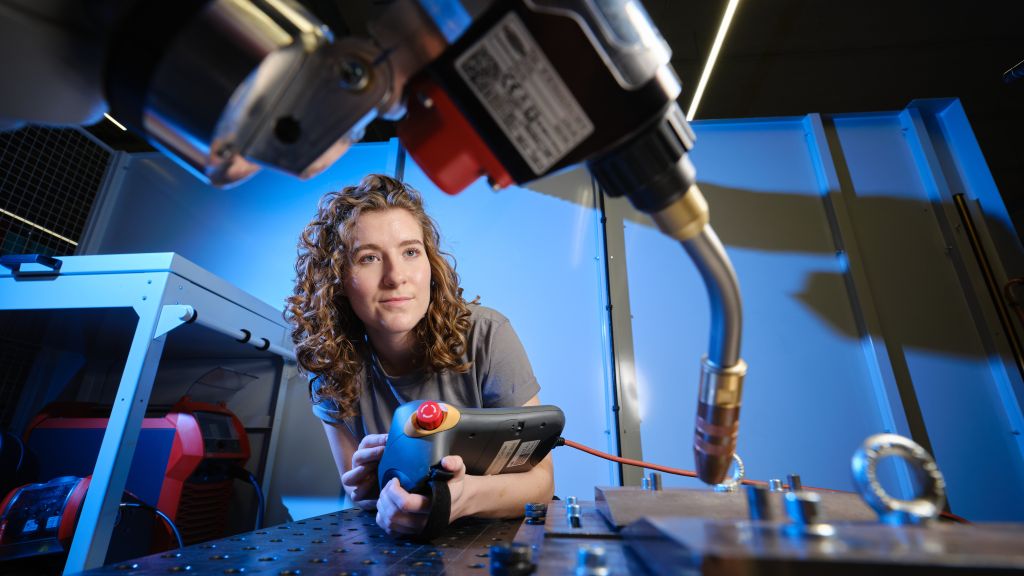

At a major truck manufacturer, installing clips on sideskirt panels had always been a repetitive task that required considerable force, carried out manually across multiple shifts per day. With the introduction of a new line of electric trucks - and a redesigned sideskirt without features like a fuel cap - it created the perfect moment to automate this process. “For a single truck, you’re looking at six to twelve panels, with up to thirteen clips per panel. You can imagine what that means in terms of volume and physical strain,” says Camelot Gilbert, Robot Control Engineer at AWL. “We were asked to build a machine that could take over this workload and make it both faster and more consistent.”

A complex task in a tight space

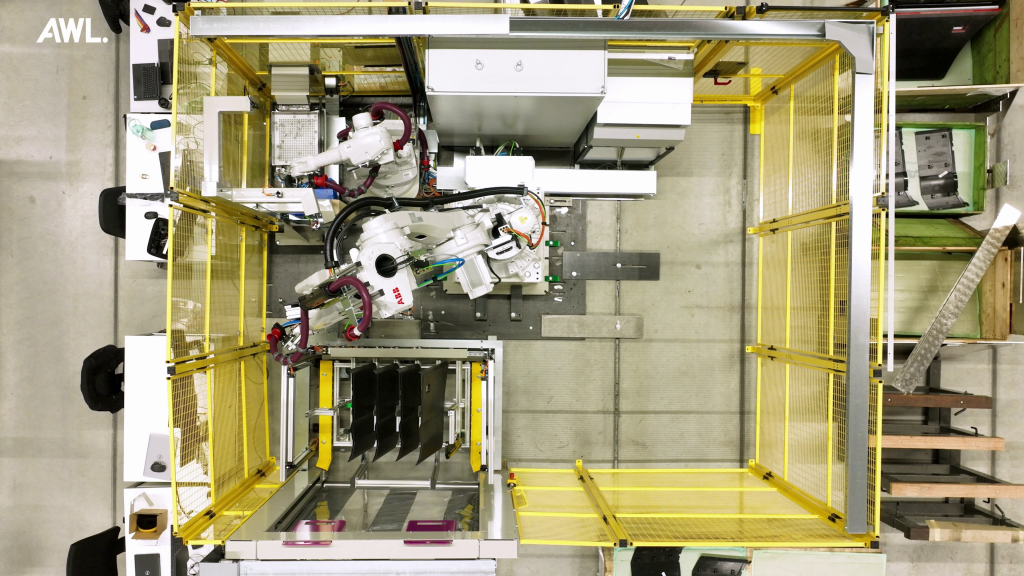

Camelot joined AWL in 2021. She started as a trainee after her studies, spending time in both the robot engineering department and R&D before becoming a Robot Control Engineer. “There were a couple of specific requirements that made this project more complex than usual,” she explains. “The footprint available in the factory was extremely limited: just 4.5 by 3.5 meters. Only half of that space was designated for the machine, leaving room for future expansion. We also had to deal with multiple product variants and freshly painted surfaces that couldn’t be scratched. And because the machine had to be installed right next to manual assembly stations, noise and visual disturbance had to be kept to a minimum.”

Engineering a custom solution from scratch

“There were a lot of challenges, but we never said: ‘That’s not going to work’,” says Camelot. “We always go the extra mile and work with the constraints we’re given and find a solution that fits.” One of the first steps was designing a custom roll cart to hold the panels. This cart did not yet exist, so it had to be developed from scratch. The panels are placed vertically by hand, and the robot then picks them up. “That sounds straightforward, but with many different panel variations, getting all of them to fit properly on the same cart proved challenging. In the initial design, the cart also lacked stability: when the robot placed a panel, the cart sometimes shifted. We kept refining and reinforcing the design and making improvements based on real testing. Small issues surfaced along the way, but that was exactly the point: extensive testing ensured the solution became not just functional, but robust and reliable in daily use.”

Smart automation for perfect precision

For this project, a compact, fully automated system was developed to install clips onto truck side panels with exceptional accuracy. “Two collaborating robots, supported by advanced 3D vision and barcode scanning, identify each unique panel and position the clips exactly where they need to go,” Camelot explains. “Smart feeding and gripping solutions ensure that every clip and panel is handled reliably—regardless of shape, color, or paint variation—guaranteeing consistent quality in a production environment full of variation.”

High performance with real production impact

“Seeing this machine run is extremely rewarding,” says Camelot. “We went from operators installing dozens of clips by hand to a fully automated process that places each clip in less than 5 seconds, with 99.8 percent accuracy.” Similar assembly challenges exist within the automotive industry, but also in any situation where flat exterior panels need to be fastened using clips on the inside. Camelot concludes: “And the best part is that operators no longer have to do this tough, repetitive work by hand.”

If clipnut installation is part of your production process, let’s explore how automation could elevate your operation. Get in touch to discuss your application.

You will also like these blogs:.

In conversation about the future of the food industry: insights from an inspiring roundtable session

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026