AI Weld inspection

move beyond manual checks

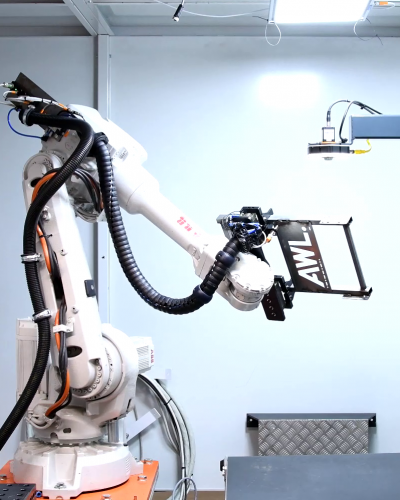

Smarter weld inspection with AI: Move beyond manual checks. AWL’s AI weld inspection solution delivers faster, more consistent, and fully traceable results and always tailored to your production process.

Manual weld inspection is reaching its limits

In automotive and metal-processing industries, quality control still relies heavily on human operators. But with fewer skilled inspectors available, manual checks are:

- Time-consuming and error-prone

- Hard to scale in growing production environments

- Difficult to track in ERP or MES systems

Meanwhile, customers demand consistent quality and complete traceability. The question is: how do you achieve both?

AI weld inspection — the smart alternative

AWL’s solution bridges the gap between manual inspection and expensive 3D systems. Using 2D camera technology combined with AI software, you can:

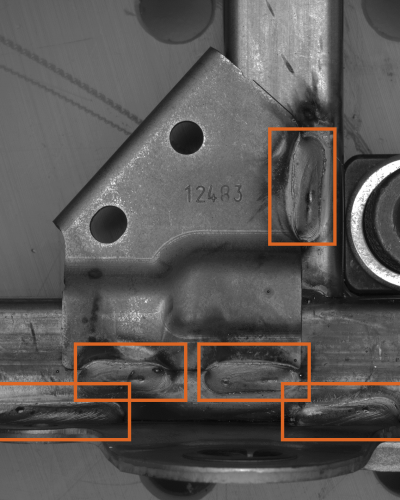

- Verify weld presence, position, and dimensions

- Detect defects such as burn-throughs, pores, discontinuities, spatters, spatter-free zones, cracks, or craters.

- Add functions like weld barcode reading

“The strength lies in the combination of simplicity, flexibility, and intelligence. It’s easy to integrate into existing production lines, adapts quickly to different products, and applies smart algorithms to deliver reliable inspection results.”

Wilbert van de Ridder – Innovation leader AWL

The key benefits

- Increase consistency & accuracy

Eliminate human error and achieve reliable inspection results. - Save time & reduce bottlenecks

Automate visual checks and speed up quality control without slowing production. - Ensure traceability

Digitally record and integrate inspection data with ERP and MES systems for full transparency. - Detect more than defects

Identify pores, interruptions, burn-throughs, and spatter. - Flexible integration

Deploy in-line or as a standalone solution, with multiple AI approaches available to match your needs.

Our technology partners

We believe in building solutions that work in practice. That’s why we co-develop our AI weld inspection solution together with leading technology partners. Each brings unique expertise in vision systems, AI modeling, and industrial integration. Our preferred partners are:

- IUNA – AI experts focused on intelligent inspection

- Vista Solutions – Industrial vision and automation specialists

Together, we ensure you always get the best fit for your production environment.

See it live and Experience the solution yourself.

Visit our Experience Center in Harderwijk, the Netherlands to see the action. Explore how AI can transform your inspection process — and discuss how it can be tailored to your production line.