Training

AWL Training

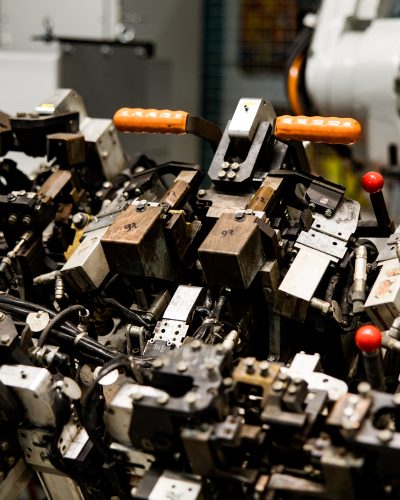

The importance of these trainings lies in equipping Operators, Maintenance & Operational Managers with the necessary knowledge and skills to efficiently operate, maintain, and troubleshoot machines. By understanding both the theoretical and practical aspects of the equipment, participants can ensure optimal performance, reduce downtime, and increase the longevity of the machinery. These trainings ultimately lead to a more effective use of the machines, improving productivity and minimizing errors or issues during operation.

01) Machine Use Training - Basic

The training enables participants to operate and troubleshoot the machine efficiently, focusing on safety and problem-solving.

Location: on customer premise

Level: Basic

Target group: Operators & Operational Managers

02) Machine Use Training - Advanced

The training prepares participants to operate, configure, and diagnose the machine, covering safety, controls, and the use of service and teach modes.

Location: on customer premise

Level: Advanced

Target group: Maintenance (electrical) & Maintenance (process)

03) Maintenance Training - Advanced

The training includes machine theory, component coding, and practical maintenance, focusing on jig adjustments, cleaning, and pneumatic systems.

Location: on customer premise

Level: Advanced

Target group: Maintenance (process)

04) Process Equipment Training - Advanced

The training teaches process management and maintenance of welding equipment, focusing on parameter relationships, position optimization, TCP adjustments, and effective use of PC software.

Location: on customer premise

Level: Advanced

Target group: Maintenance (process)

05) Robot Use Training - Advanced

The training familiarizes robot engineers with software, routines, AWL commands, I/O controls, and message troubleshooting, followed by hands-on practice.

Location: on customer premise

Level: Advanced

Target group: Maintenance (process)

06) Machine Diagnosis Training - Advanced

The training focuses on troubleshooting complex machine issues, using the HMI and electrical drawings to solve problems, and knowing when to contact AWL service for assistance.

Location: on customer premise

Level: Advanced

Target group: Maintenance (electrical) & Maintenance (process)

07) Machine Diagnosis Training - Expert

The training teaches how to quickly diagnose issues using the PLC program, understand its structure, and apply diagnostic tools to resolve common errors.

Location: on customer premise

Level: Expert

Target group: Maintenance (electrical)

Contact for training

Send us a message and you will receive a response within two working days.