AWL the connecting factor in the Logistics Market

Published on: Jun 30, 2021

By Matthijs Varwijk - Business Development Logistics

As I work on developing a go-to market strategy, I am often asked how AWL can make the difference in the Logistics Market. What is our added value in this field? In this blog I share my experiences in this area with you.

Today’s market

AWL has been active in the Automotive Industry for decades and in addition has also earned its spurs in the General Industry. Primarily in the area of robot welding and assembly. We saw that with our current machine concepts we started performing increasingly more logistics movements. Instead of having an operator manually place parts in the machine after which a robot took them to the next station. The Automobile Industry on several occasions asked us about the possibility of increasingly automating various aspects. In other words, without the need for an operator. That requires vision technology, such as bin picking. We took these steps over the past three years.

Logistics Market

We are aware that logistics processes, especially in our present times, are tremendously important. The Logistics Market is under pressure. Players are either submersed in problems or perceive the tremendous opportunities for growth inherent in these times. But at the same time the situation is such that they are no longer able to cope with the demand. They either have to scale up and employ more people or they have a need for more technologies. In addition, consumers have become spoiled. When they place an order before 23:59, they expect to have it delivered the next day around 14:00. Just do the math: it means you have to work very hard at night to get this done. We understand that the logistics sector has generated a tremendous demand for automation.

The challenge

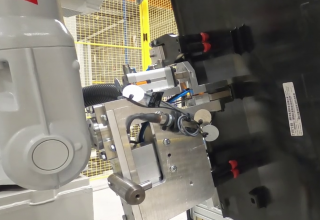

We already saw that in the Automotive Industry, robots move parts from one location to another. But in the Logistics Market these ‘parts’ are packages and are therefore never the same. They differ in terms of size, weight, etc and are never oriented the same way. This means that it is important to have the right ‘eyes’. That you apply the right vision technology so that it ‘recognizes’ the package. That you have the right ‘hand’ or gripper and that the package ends up in the right place. That requires an effective machine concept with a robot that brings the package from one location to another. This is where AWL, with the knowledge it has gained of robotization, can make a difference.

Our experience

Of course we understand that every warehouse and every end client’s operation is different, because the package is never the same. The human being in this entire operation is extremely smart and can really do everything. Today, the software is also smart, but that does not mean that it can do everything. What we have learned in the Automotive Industry is that you must do everything well. But you also have to give careful thought to your machine concept when everything is not OK. In other words, what is your NOK (NOT OK) strategy? With the right machine concept you can ‘pick up’ almost anything, but when things don’t work, you must also have a good concept readily at hand to deal with that. Why? Ultimately you must have a stable system that simply runs and generates the right output. That achieves the numbers demanded of it. In other words, the business case must be viable and the machine industrially robust.

Vision technology is becoming increasingly more important

You can see that the entire market is in flux and that vision technology is becoming increasingly more important and must be applied the right way. Currently there are a number of e-commerce players that are taking the first tentative steps and this number is only going to increase. When you consider these potential clients and they in turn look at the market, they see that start-ups are tremendously increasing in value. They are being bought up. But these start-ups work on the basis of very different philosophies; they have grown up from their university roots. If you want to roll out new technologies on a large scale with these parties, you must be solid yourself as well. You need a party that builds an excellent machine that is reliable and stays up and running. In addition, you must be able to offer worldwide services. Furthermore, if you are going to implement new technology, it will not stay at just one technology. Because this market is undergoing strong growth and once it catches on, you have to be able to scale up.

Connecting link

As AWL, we connect various parties; in our role we consider bringing all parties together important. This also includes the four large robot suppliers: Yaskawa, ABB, Kuka and Fanuc. They are indispensable in this domain. The large material handling providers are the suppliers par excellence of the logistics sector; they fit up entire warehouses. If you are interested in taking this new step towards robotization, you must also be a connecting factor in one way or another. First, you have to set down a machine in the environment of such a material handling provider. This is not one small, but many large warehouses globally with multiple systems in multiple countries. Second, you must have a robot that can be effectively integrated. Not just one type, but brand independent, because that strengthens your position in the market. In addition, you must be flexible enough to be able to interact with the trendy start-ups as a means of effectively deploying vision technology.

I believe this is where AWL can make a difference for end clients, because we are exactly positioned at the center. We are large enough to deal with the large handling providers, to supply systems for warehouses, and creative and skilled enough to integrate and optimize new vision technology into our systems. Furthermore, not least important, we are independent and have already installed more than 3,000 robots throughout the world.

You will also like these blogs:.

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026

Small footprint, big impact: automating sideskirt clipnut assembly