The Fashion Industry

The dynamics of the fashion industry are changing considerably and the market is growing faster than ever. Consumers are not only looking to gain access to the latest trends, but they also want to enjoy the highly demanding shopping experience. This concerns purchasing as well as returning products, preferably to a location of their own choice.

The Fashion Industry and its Challenges

As a result, clothing shops are faced with a number of unique challenges:

- Increased pressure to tackle rising operating costs linked to a lack of available personnel, intensive operator training and the need for shorter lead times.

- Unpredictable demand and seasonal trends in the fashion industry.

- Increasingly higher return volumes.

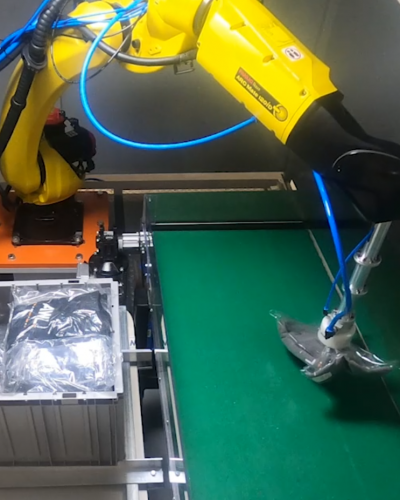

Robotization can help address these issues and AWL is happy to contribute its ideas to help solve your particular problems. The robotization of your distribution center makes the working environment for your personnel considerably safer and more ergonomic. Heavy and repetitive work results in lost personnel time due to physical strain. The deployment of robotics and advanced technology designed to pick or unstack totes, boxes and bags means that your personnel can add value to your operation in other areas.

The First Step

Determining the ‘pickability’ of a certain set of SKUs by robots is the first step. While apparel, which consists of highly pliant products and irregularly shaped packaging, presents a significant challenge, this is not a problem for AWL thanks to our combined robot, gripper and vision technology.

From Returns as a Problem to Automation

The promise of easy returns, sometimes free of charge, has become a key characteristic of the online clothing retail sector instead of problem. Investing in automation is the answer to meeting this demand, facilitating the returns process and replacing the returned goods in the warehouse. This helps keep labor costs low and also reduces the costs associated with erroneous picks.