Assembling game-changing automation

Published on: Feb 2, 2023

Logistics Tech Outlook magazine offers professionals the most widespread collection of technology information for the logistics market. For an article in this magazine, our colleagues Arjen Vos (Director Strategy & Development) and Allart van de Schootbrugge (Account Manager) were interviewed to provide insight into AWL's game-changing robotic solutions for the logistics sector.

The long-troubling human factor in the logistics market elicits the crucial question, "are companies equipped with enough hands to do the real work and against an acceptable cost level?" Further compounding this labour mismatch is the repetitive nature of the work combined with increasing consumer demands for faster and even specific delivery times. In the wake of a skilled labor shortage and rising labour costs, the logistics industry is turning to automation to replace the routine tasks of picking and packing goods in the warehouse.

Force multiplying automation with its game-changing solutions for the logistics industry is AWL, a high-tech machine builder specializing in technology integration, logistics automation, and assembly techniques. AWL solves numerous operational and labor-related logistics challenges with its robotic singulating and depalletizing machines, ROSI and RODE, respectively. Material handling providers that work with machines can easily integrate AWL's robot modules into their systems. Its industrial robots are vigorously built for the warehouse environment.

Optimized vision systems

AWL's robotic singulating and depalletizing solutions remove human labour from piece and item picking as well as from sorting and singulating parcels in e-grocery and parcel post distribution. The company's optimized vision systems are especially beneficial in industries where robots are unable to distinguish a certain set of SKUs from inventories such as apparel, which often have irregular packaging.

ROSI

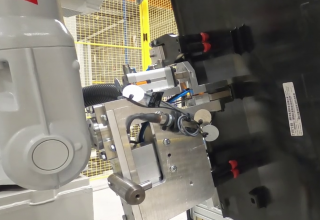

ROSI is designed with high-tech gripper technology to carefully handle customers' parcels with the capability to complete up to 1,700 picks per hour. Built with deep learning vision software, ROSI offers optimized lighting conditions, which allow it to easily recognize similarly coloured items from bulk or sorted goods. Compact and mobile, ROSI's Plug&Play capability allows it to be both versatile and suitable for any task that involves singulating.

RODE

AWL's RODE is a random mixed depalletizing solution that is integrated with advanced machine learning and also utilizes soft-gripping technology to carefully handle parcels. Built with vision software, it determines grasp poses per item and optimizes speed by measuring weight on-the-fly. RODE has the ability to carry out reorientation of the parcel based on label detection and requires no human intervention to pick boxes from unstable stacked pallets.

Competent centre of engineers

As a result of being in the automotive business, AWL's emphasis on industrial robustness along with its creativity and competency in engineering is what sets the company apart. It has a competent centre of engineers that are able to address any unforeseen circumstances that can arise in projects. Logistics customers are often anxious to step into robotics because of such unpredictable circumstances, but AWL's Experience Centre showcases its ability to help customers and prove its commitment to the job.

R&D teams with focus

When setting out into the logistics markets, AWL envisioned being an enabler, in order to move the market as a whole further into automation. The company set up several teams within its R&D department to focus on vision, gripping, robotics and vacuum technology. The teams continue to investigate available techniques to develop or combine and integrate into one machine and test them.

Maximum performance

AWL stands unique among its peers in material handling as it zeroes in on refining the process of developing a solution rather than just the solution itself. If a machine with vision and gripper technologies does not work properly, AWL works on integrating these parameters on a higher level to yield the maximum performance.

Innovation roadmap

The company's novel approach to formulating ideas and technologies on an innovation roadmap for the logistics market, also separates it from its automotive peers that opt for more project-based delivery. Miles ahead with its vision technology and vision knowledge paired with its 30 years of experience in robotics, AWL is proving to be a game changer in warehouse automation.

AWL’s robotic singulating and depalletizing solutions remove human labour from piece and item picking as well as from sorting and singulating parcels in e-grocery and parcel post distribution.''

Source: https://www.logisticstechoutlook.com/awl

Questions? Go to www.awl.nl/contact.

You will also like these blogs:.

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026

Small footprint, big impact: automating sideskirt clipnut assembly