Sander Lensen of AWL about smart robotic solutions and vision technology

Published on: Apr 19, 2022

Sander Lensen, Technology Manager at AWL, has written a blog about smart robot solutions and vision technology. Read more about his findings here.

Sander Lensen of AWL about smart robotic solutions and vision technology

As Technology Manager at AWL I am seeing that the market has a need for flexible machine concepts. Vision technology plays an increasingly more important role in this. In this article I am pleased to be able to share my insights with you about how AWL anticipates this changing market.

What is vision technology?

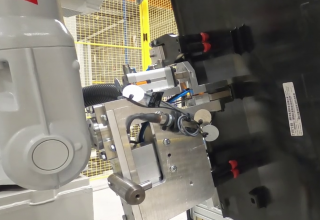

When people talk about vision, the first thing that often comes to mind is its literal meaning: to see something. In fact this is also the basis of this technology, and for the applications we are using it means that we enable robots and machines to see. Vision technology always starts off with an optical sensor. This sensor produces data and makes it available. When we think of vision technology, we often think of optical 2D or 3D cameras, but distance sensors or laser sensors also are vision sensors. The latter application has proven to be very interesting for our logistics customers, for example for accurately determining the position of boxes. What we can generally say about vision solutions is that on the basis of collected data we are able to perform analyses, calculations and draw conclusions to control machines. For AWL this means that we are able to develop even smarter robot solutions with the aid of vision technology.

Why do you think this technology trend is on the upswing?

It is not new, the technology has existed for some time, but a visible trend has recently emerged. We see that the market is ready for flexible machine concepts and vision technology is an enabler. This means that for a wider range of products you can deliver the same machine solution. An additional benefit is that a vision application can reduce the machine’s mechanical complexity. In the past, customers asked for machines that would always produce the same product or perhaps two or three combinations thereof. What we are seeing now is that requests are becoming increasingly more complex. It is becoming increasingly more difficult for our customers to foresee in advance how many products of different product types need to be produced. The challenge for us is therefore to manufacture machines that are capable of producing many different products. The game changer hereby is that vision is being used for intelligent guided robotics. Robot movements are no longer programmed by default, but are created by smart mathematical models and advanced software. The software enables the robot to handle variation.

Looking for automated solutions

In the past production often ran with the aid of an operator. This has continued to decrease in recent years, because it has become more difficult to find personnel capable of performing this work, there is a tight labor market and the work is too repetitive. At the same time labor costs are rapidly increasing. This is why companies are looking for automated solutions for production-critical processes.

AWL makes use of vision technology in three different markets

At AWL we apply vision technology in the logistics, general industry and automotive sectors. However, we do not make use of this technology the same way in these three markets. We often make a distinction between metals and logistics products. The technologies we use for metal products can be applied in the automotive sector and in general industry. What we often see here is that we need to recognize objects and determine their position. Or we need to calculate their geometry and this can be done with the same algorithms. The process for metal products must always be carried out with high precision. For example for welding or for precisely positioning materials.

In the logistics sector, this rather involves parcel recognition and finding surfaces on which to place the suction cups. Positioning here does not have to be as precise. Putting away a parcel may be relatively inexact, as long as it falls within a demarcated area.

What is AWL’s added value?

As system integrator we are capable of facilitating advanced production processes on the basis of our knowledge of machine technologies combined with robotic solutions. Intelligent guided robotics is the future in this respect! Due to our knowledge of the various solution components we are able to achieve greater flexibility, which means that our customers are less dependent on mechanical components. This reduces the need for retooling for new versions and provides for automation that previously was not yet profitable.

I am therefore convinced that at every customer there is a process with a mechanical solution for which vision technology today provides a better solution option. This creates flexibility and new possibilities! We are happy to explore the possibilities together with you.

If you would like to know more about vision technology and its potential benefits for your company, contact me for a demonstration in our Experience Center in Harderwijk in the Netherlands.

You will also like these blogs:.

In conversation about the future of the food industry: insights from an inspiring roundtable session

Meet The People | Jorgan Newell: From Sales Engineer to Engineering Team Lead at AWL US

New co-CEOs at AWL as of January 1, 2026