Body components

We will be happy to provide you with advice at an early stage.

Uncertainty prevails among OEMs in the automotive industry about production volumes. With the younger generation now less likely to buy a car and car ownership in big cities becoming less attractive, how many cars should be produced? Sharing cars and autonomous driving are also trends that present challenges.

The answer to today’s challenges

AWL responds to this with its machine solutions. This means you can use one machine for multiple parts for several car models. The machine is also scalable based on the volume demand, saving space on the floor as well as investment costs.

The automotive industry sets high demands on innovation, quality, 24-hour volume production, flexibility in product variants and short lead times. AWL guarantees you a turnkey production process that satisfies your demands.

We have years of experience with OEM design requirements, both for the automation concept and for the product design itself. We know the requirements for the components, we provide input for the product design and master the various joining techniques used therein. In our machines, we use state-of-the-art techniques in which our engineering and process knowledge are invaluable.

The unique machine concept of AWL

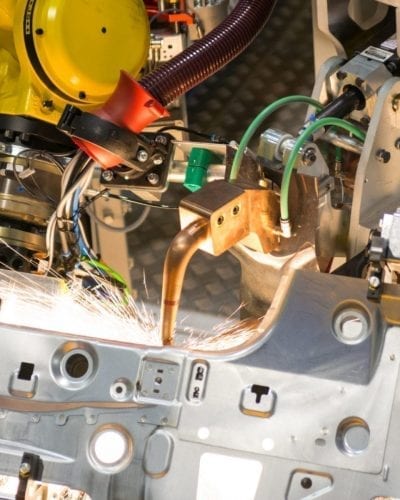

AWL machines are used for body components such as cross members, roof frames, A, B, and C pillars, side members, cockpits and doors. Safety plays a crucial role here. After all, the bodywork constitutes the physical protection between the passenger and the outside world. Our machines work with the latest technologies in the field of laser, spot and arc welding with integrated systems for glued joints, stapling, clinching, vision systems, product handling, quality control and traceability.