Resistance welding

A known technique, fast and reliable

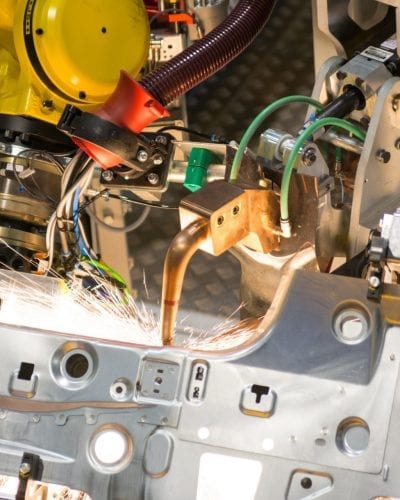

For high volumes, resistance welding is the ideal joining technique: fast, reliable and it can be perfectly automated. Not surprising that on average, the bodywork of a car is spot welded 3,500-5,000 times. As a system integrator, AWL has extensive experience in the application of the resistance welding technique, both in robotic spot welding and in building machines for projection welding for very diverse applications.

Although this technique has been known for years, there are always important new developments. For the spot welding of aluminum, for example, new adaptive controls are being developed in the welding controls with the use of force sensors. AWL works together on this with reputable welding control suppliers.

Spot and projection welding

Spot welding is very often used to connect steel parts with each other, but this technique can also be successfully applied for aluminum. Projection welding is used among other things to weld nuts, bolts, and pins to sheet metal parts. We have developed various machine concepts at AWL for this.

Quick Motion – a faster method of spot welding

Our spot welding competence is stable, flexible and fast!

Short cycle times, efficient use of space and simple operation are prerequisites for spot welding activities in the highly demanding automotive industry. Our Quick Motion configuration offers optimal flexibility and high speed. AWL has developed this configuration, which significantly shortens weld-to-weld time. Quick Motion enables us to weld your product from point to point in under two seconds.

Research and development

AWL has been a recognized expert in spot welding for 30 years. We are continuously pushing the boundaries of technical possibilities in close collaboration with universities and suppliers.

AWL participates in projects that examine how spot welding can also be applied for connecting fiber-reinforced plastics through the use of metal inserts. There is an ongoing study investigating how the electrode service life can be extended when spot welding aluminum, with the ultimate goal of increasing machine output.

Spot welding aluminum is more complex than steel in terms of process windows, electrode service life, parameter determination and quality control. By expanding our knowledge of these subjects, AWL is prepared for future projects with aluminum spot welding and we can offer you equipment with reliable processes.