Food Retail

The food retail sector is one of the most challenging sectors from a logistics perspective. Supermarket distributors ship large quantities of goods to retail outlets with regular deliveries to guarantee product freshness. Operations in food distribution centers are among the most labor-intensive of any business sector.

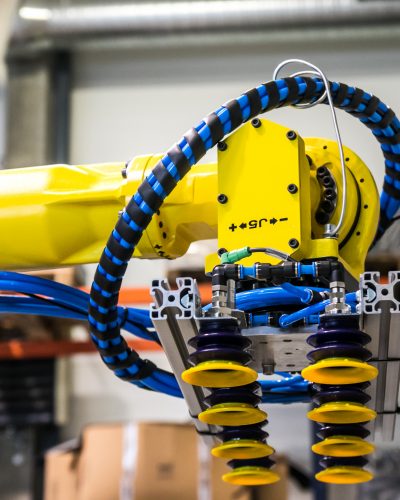

The work is physically demanding with many employees who are required to handle heavy boxes with goods and who have to work in cooled environments and deep freezers the entire day, at high speed. This can now be done more ergonomically, efficiently and accurately thanks to automated robot solutions.

In the current, highly mechanized food retail industry, there are still few robots to be found at the present time. In this environment goods are brought to people (goods to person), who subsequently manually pick the goods and place them in a box. This process is easy to automate thanks to our Piece & Item Picking solution.

In contrast to traditional robots that are only capable of performing preprogrammed tasks, AWL’s picking solutions can adapt themselves to dynamic industrial environments and deal with unpredictable situations. Order picking is the most labor-intensive part of the distribution center and ideally lends itself to automation. Manual pickers can still be tasked to pick non-pickable items, while order picking robots can concentrate on high-volume items, thus saving on manual labor and costs.