Adhesive bonding

Automated adhesive bonding with robots and cobots

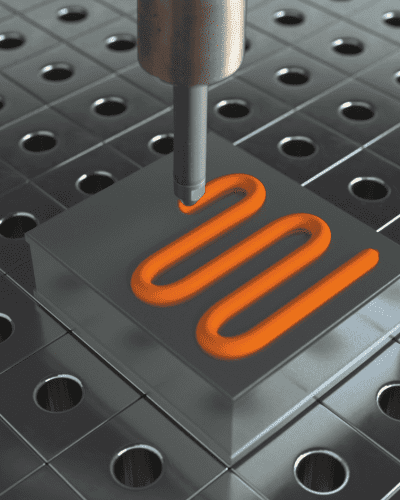

Automated adhesive bonding is a technology that has been on the rise, both on its own as well as in combination with other joining technologies, such as clinching (joining of thin metal sheets without any additional components or warmth) and spot welding. Adhesive bonding is being increasingly used, especially in the automotive industry.

Fully automatic adhesive bonding with robots and cobots

AWL is a system integrator with extensive experience in integrating bonding equipment on robots. As a result, the parts are glued fully automatically and with constant high quality. For smaller series, gluing with cobots is also interesting. Due to the high quality requirements that are set for glued parts, control and traceability are important aspects of the production process. This functionality can be integrated on AWL machines.

Advantages of bonding

Adhesive bonding provides a continuous joint between the parts. The application of glue in the bodywork delivers extra rigidity and crash safety. Adhesive bonding is the ideal solution for joining different materials, such as steel and aluminum or metal and plastic. Adhesive bonding is also used for making parts watertight, or supporting thin plates. This joining technology is frequently applied in car doors, battery housings and engine hoods.

Take advantage of our specialist knowledge

AWL has in-house knowledge of European Adhesive Specialists (EAS), certified by the German Fraunhofer Institute BIAS in Bremen. This gives AWL the fundamental knowledge to work with you on developing an optimal adhesive bonding process for a specific application.

We have built an extensive portfolio of successful adhesive bonding projects and we look forward to making a success of your bonding project too!