Laser welding

The main advantage of laser welding is the speed and precision

Besides speed and precision, laser welding offers high productivity, new construction possibilities and cost savings. In order to guarantee a fast-welding speed and a reliable process, the product design, jig design, integrated airflow and other preconditions must be of the highest quality. Moreover, innovation is deeply rooted in our DNA, leading to very successful projects for our customers.

Our experience

With over 17 years of experience and 180 laser welding machines sold, which have already produced millions of high-quality parts, AWL is the ideal partner for you. Examples of industries in which these machines operate: car seats, body-in-white components, tubular products such as fittings, industrial cabinets and batteries.

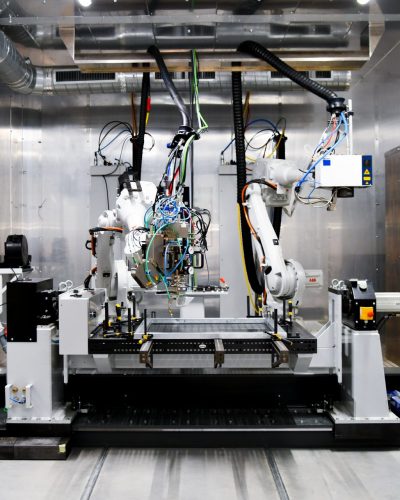

The design and construction of a laser welding machine requires broad knowledge of many aspects of both welding and machine building. After a consultation or workshop, we can manufacture test parts in our Experience Center using our very high-powered laser welding machine. There, our experts make their knowledge available to your project.

The heart of each welding machine is the jig. AWL has extensive experience in designing stable and reliable jigs. For the machines, AWL integrates the most advanced components and is open to the integration of various brands of lasers and robots. This enables us to adapt as well as possible to the customer’s requirements.

Whitepaper 'Laser beam welding with concentric focal points increases productivity'

Lightweight materials

The pursuit of a higher output and the use of lightweight materials, such as aluminum and high-grade steel, requires alternative joining methods. Aluminum is much lighter than steel and more affordable than fiber-reinforced plastic or magnesium. The rise in popularity of electric cars boosts demand for lightweight solutions, increasing the range of the vehicle and compensating for the weight of the batteries. Laser welding has favorable properties for the joining of aluminum and high-grade steel, such as: low heat input, high welding speed and short intervals between the welding.

Cost savings

Using laser welding on products with high production volumes, long weld seams and/or many subcomponents results in impressive savings. These savings are primarily due to the high welding speed, the short intervals between the welding and the short changeover times. Furthermore, in cosmetic welds, directly visible to the customer, often manual finishing operations which would be needed after arc welding can be discarded when using laser welding. In industries such as the furniture industry, this can result in very significant cost benefits.

OCT

Optical Coherence Tomography (OCT) is a new laser welding quality control method. With OCT it is possible to produce a very fast (> 100 kHz) and accurate distance measurement between welding head and workpiece. This makes it possible to measure the following during laser welding:

- The depth of the keyhole and as such the depth of the laser weld

- The shape of the seam before welding, as input for a seam tracking system

- The shape of the seam after welding, as input for a quality monitoring system

OCT in practice

AWL, together with specialized suppliers, has conducted experiments to test OCT in actual practice. During the test, the OCT system was mounted on a laser scanning head and on-the-fly measurements were performed in a real production machine to test the system. This has yielded valuable information about the OCT system’s possibilities and for its further development. The ultimate goal is to develop a laser welding system with real-time control of the welding depth, so that quality, even in case of disruptions, is always guaranteed.

Laser welding with beam shaping

AWL has installed a promising new technology in its Experience Center, beam shaping. We conducted tests using the Trumpf Brightline weld technology. This is a form of beam shaping for laser welding that, rather than making use of only a single focal point, projects a small focal point onto the workpiece in the center of a larger focal point. The advantage is that the small focal point stabilizes the keyhole during laser welding: this makes higher welding speeds possible and reduces weld spatter. AWL has since applied beam shaping in a number of successful customer projects. In-depth research into additional beam shaping opportunities will be conducted in the near future, including the benefits for our customers.

Simple robot programming

In the past, most laser welds were overlapping seams. In recent years, AWL has successfully focused on adding non-overlapping laser welding with industrial robots to the portfolio. The unique software tool we developed, the AWL GeoEditor, enables simple robot programming for these demanding applications.

Innovations

At AWL, experts work continuously on the further optimization of the machines. These innovations include improving productivity, such as the latest developments in the field of robotic laser welding – laser welding with a scanner head on a moving robot – or improving quality, for example in laser welding that is optimized with CFD (Computational Fluid Dynamics) technologies, in which the flow of air required for a high welding speed is optimized by means of numerical simulations.

Are you interested in our laser welding solutions?

Contact us!