Manufacturing of bipolar plates

In our world today, everything revolves around the energy transition. It is a topic that has become impossible to escape. The energy transition creates new opportunities. We see that the demand for hydrogen as an energy carrier is increasing. AWL supports the transition to sustainable energy solutions and has become an important player in the supply chain.

AWL has many years of experience with laser welding and automated welding solutions, including quality control. This knowledge and experience form an important basis for the development of automated production machinery to manufacture hydrogen fuel cells and electrolyzers.

Fuel cells are a crucial component in the hydrogen transition

Green hydrogen is produced with the help of green electricity and so-called electrolyzers. This hydrogen can subsequently be converted into electricity with the help of a fuel cell. Bipolar plates are needed for the manufacture of electrolyzers, as well as fuel cells. They form the heart of the fuel cell or electrolyzer, route the hydrogen and oxygen through the fuel cell, and contain the cooling channels. A single fuel cell contains hundreds of bipolar plates.

Expert in welding, automation and quality control

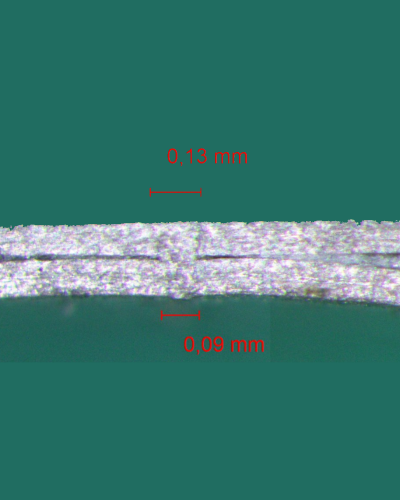

Bipolar plates are made of thin (0.1 mm or thinner) stainless steel and must be laser welded leak-tight. This is a major technical challenge that AWL tackles by means of its decades of experience with laser technology, automation and quality control. We are accustomed to working with demanding clients in the automotive world and in complying with high quality and productivity standards. This experience gives AWL a head start in the field of hydrogen technology.

Process steps for the production of bipolar plates

AWL can provide various processes for the production of bipolar plates. Aside from welding plates, the production process includes various pretreatment and post-treatment steps. This starts with the meticulous, automated inspection of the plates for contamination and defects. Image recognition algorithms and artificial intelligence are used for this purpose. Contaminated plates must be cleaned to be able to guarantee welding quality, leak-tightness and the ultimate functionality of the bipolar plates. After the plates are joined together, they are welded to create a bipolar plate.

After virtually every process step, the product is inspected, ranging from optical inspections to a leak-tightness test after welding. This avoids expensive or time-consuming processes, such as coating, from being applied to products that are already defective and ensures that the end-product meets the strict quality requirements.

All of these processes can be used on a transfer line in a different order and in any quantity. This makes the line modular, scalable and flexible.

Do you want to take the next step in the energy transition together?

A modular machine line

Thanks to the modular machine line, you are at the right place at AWL for all your needs; regardless of whether you would like to produce 100,000 bipolar plates, wish to upscale or immediately start up a production line to manufacture 20,000,000 plates, we are able to deploy the modules that are needed for your process. Furthermore, once the line is in production, we can add additional modules to increase production capacity as demand increases.

Quality is a high priority

AWL uses its knowledge of vision technology to successfully perform quality control. Special illumination combined with an artificial intelligence-based inspection algorithm has made the automated inspection of welds possible.

We also make full use of our extensive experience with inline weld monitoring systems.

Other benefits

- Redundancy

The machine has been developed such that when a certain module fails, it does not bring the entire machine to a standstill. This ensures that it is still possible to achieve high output during maintenance or the failure of individual machine components. - Traceability

Every product produced by the machine is fully traceable. Every plate is provided with a unique DMC code to which the production data is linked and from which it is possible to retrace when and with what parameters the product was produced.

Taking the next step together in the energy transition

AWL would like to assist you in developing the process design for your process chain. Feel free to contact us for more information or to make an appointment.