HI, I AM ROSI.

And I singulate packages. ALL. DAY. LONG.

ROSI - the robotic singulator

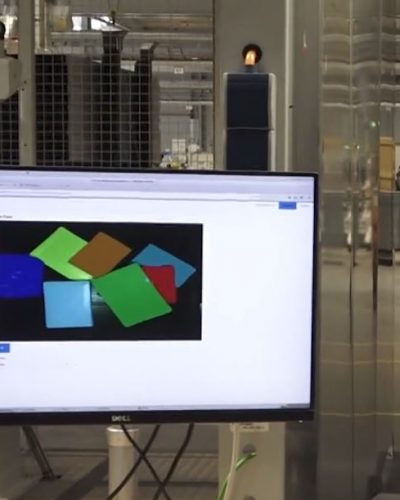

ROSI can help your company with item picking, sorting, singulating, small parcel handling and other tasks. ROSI adapts to scope with dynamic industrial environments and unpredictable situations rapidly. She does this with an expert combination of robot, gripper, and deep-learning vision technology.

ROSI's specifications

- Up to 1,700 picks per hour

- Footprint of 1,825×1,180mm

- Also available as ROSI Compact (footprint of 745 x 530 mm)

- Singulation accuracy up to 99.9%

Robotic singulating of packages with sorting option

Applications

- Robotic sorter induction

- Robotic item & piece-picking

- In combination with a tipper able to depalletize

AWL's ROSI integrated to EuroSort's sorter

Collaboration Fizyr

As an independent system integrator, AWL works together with various suppliers of robots, vacuum technology, and vision software, for example. To serve the logistics market even better, we have entered into a partnership with Fizyr, a vision software supplier. By integrating their software into our machine, automated picking in harsh logistics environments is possible.

Wondering what AWL can do to automate your logistics processes? Contact us!

AWL-Techniek Holding B.V.